Oxalis tuberosa es un tubérculo originario de los Andes, el cual es usado principalmente para el consumo en el hogar. Sin embargo la combinación de la harina de este tubérculo con almidones puede emplearse para la producción de productos libres de gluten principalmente para las personas que sufren de celiaquía. En este estudio se realizó un pan empleando esta harina y una mezcla de almidones. A la masa y al pan se les evaluaron sus propiedades reologicas mediante el análisis de perfil de textura y la prueba de extensibilidad, encontrando que el parámetro de dureza fue mayor en la masa libre de gluten en comparación con una masa testigo elaborada con harina de trigo. Se observó que este parámetro incrementaba de manera proporcional a la adición de Oxalis tuberosa (OtP), mientras que los parámetros de cohesividad y elasticidad disminuyen, lo que afecta la textura y volumen final del producto. El tratamiento 2 suplementado con 10% Oxalis tuberosa pregelatinizada fue el más cercano al control presentando una menor dureza y una mayor cohesividad en comparación con los otros tratamientos adicionados con esta harina. En la evaluación sensorial no se encontró una diferencia estadísticamente significativa entre este tratamiento y el testigo.

Palabras clave: Oxalis tuberosa, libre de gluten, pan, propiedades reologicas

Oxalis tuberosa (Ot) is a tuber of Andean origin used mainly for home consumption. The combination of flours and starches used for the production of gluten free products intended mainly for people with celiac disease. The texture properties of dough and bread are measured in the rheological tests texture profile analysis (TPA) and extensibility. Found that increased hardness parameter in the gluten-free dough compared to wheat flour increasing as pregelatinized Oxalis tuberosa (OtP) was added, contrary to the cohesiveness and springiness, diminishing and affected the quality of the final product structure and volume. The treatment supplemented with 10% (T2) of OtP was the one that took a closer control made with wheat flour (TTR) improved behaviour and properties of gluten-free controls (TGF) presenting a lower hardness and cohesiveness more. In the affective sensory evaluation were no significant differences (P> 0.05) between TTR and T2 were found.

Keywords: Oxalis tuberosa, gluten-free, bread, rheology properties

The Ot is a tuber of Andean origin that dates back more than 8000 years, can be grown in very high terrain and cold climates. But after the conquest step part of the "neglected crops" as their production and consumption were not significant.

The nutritional contribution of Ot (Cajamarca, 2010) shows that a considerable protein content (15.9%) to be a tuber. In Mexico the Ot has different names: red potato, potato-cassava, English potato or foreign potato. Bread has been since the dawn of civilization one of the main food products, its structure consists of a solid foam produced from proteins (gluten) and starches derived from wheat flour, the main objective of these elements is the retention of gas (CO2) obtained from fermentation and retaining ingredients of the dough. Obtaining a low density product while wetted inside (Lagrain, 2013). Gluten is a protein network, conformed of gliadin and glutelins, which is formed during the hydration and kneading by mechanical action (disulphide bridges).Wheat starches for bread making has the function of moisture absorption with increasing temperature. It also serves as food for the yeast by enzymatic action when they are hydrolysed. Pregelatinized starches improve the functional properties of the starches as water absorption level allowing a smoother and greater shelf life product. They are made from a hydrothermal treatment (extrusion), where the humidity, temperature and residence time in the extruder may vary according to the material being worked (Fernandez, 2013). The gluten-free bread is a bread product made from a mix of flour and/or starch, gluten free. The origin of these has its principles because of celiac disease (gluten-sensitive enteropathy) is a disorder of digestive functions of the small intestine caused by the ingestion of gluten (WGO, 2012). Currently in the US affects 1 in 133 and in Europe affects 1 in 150-300 (Demirkesen, 2014). People with this disease cannot eat foods containing barley, rye, oats, triticale and wheat. Although food technology currently allows to offer the market substitutes for original products being gluten-free bakery products of these variables. The way to mimic the structure of a bread made with wheat flour is by a mixture of flours and starches mainly maize, cassava, rice or potatoes which are linked with hydrocolloids that allow form a cohesive dough addition to providing aroma, retain moisture and help form a structured crumb (Demirkesen, 2014). The aim of this study is to evaluate the influence of OtP flour on rheological properties of gluten-free dough and pan bread quality of preserving the quality parameters of a bakery product.

2.1 Materials

The OtP flour was extruded in an extruder Beuterspacher 1.5HP 220V CEPROBI-IPN, with conditions: inlet 50 °C, cooking 60 °C and exit 80 °C at 70rpm. Proteins were determined by Kjeldahl method yielding a 6.03% protein. Wheat flour (San Antonio 3 estrellas), salt (La Fina), sugar (Zulka), dry yeast (Nevada), albumin (Pro-Winner), milk powder (Nido) and water was used for the dough were acquired in local markets. For gluten-free dough, rice flour (3 estrellas) and corn-starch (Maizena) was used, they were linked with Xanthan gum. Gluten free treatments consisted of substituting corn starch 5, 10, 15 and 20% for OtP flour.

2.2 Bread making procedure

During preparation of the bread formulations follows the methodology recommended by Channona-Pérez (2007). First, dry ingredients (flours, instant yeast, sugar, salt and gum) were mixed thoroughly, and then water were added slowly and mixed for 3 min at 85 rpm and then 2min at 140rpm using a mixer (Kitchen Aid, 5K45SS, ELKGROVE Village, USA). After complete mixing, it put in loaf pans. The fermentation was done for 40 min. Bread formulations was baked in a oven at 200 °C for 30min. Gluten-free bread and wheat bread prepared without OtP flour were used as control.

2.3 Rheological tests

2.3.1 Dough TPA

For TPA, 25g of dough simple was compressed to 20% of their original height with a 36mm diameter steel probe (TA-AACC36) in a CT3 Brookfield Texture Analyzer equipped with a 4.5Kg load cell. A constant crosshead speed of 2mm/s and a 5s waiting period were employed. From the force-deformation curves, the textural parameters defined as follows: hardness, peak force during first compression cycle, define as the force necessary to attain a given deformation; cohesiveness, ratio of force are during second compression/force area during first compression, defined as strength of the internal bonds making up the body of the product; adhesiveness, area under the curve, defined as dough adhesion work and springiness relates to the height that the sample recovers during the time that elapses between the end of the first compression and the start of the second compression (Bourne, 1978).

2.3.2 Dough extensibility test

Dough extensibility was determined by Kieffer Doug extensibility test and was carried out in same texture analyzer with the Kieffer dough and gluten extensibility ring (Texture Technologies Corp.). Dough was clamped between the two plates of Kieffer ring, pulling simple at a constant rate of 0.5mm/s. From force-distance curves, extensibility parameters were calculated as follows: extensibility, as the distance to rupture and maximum resistance, maximum force detected as indicator of dough resistance (Kieffer et al.1998).

2.3.3 Bread texture properties

Bread texture was determined via TPA. Bread TPA was conducted on bread samples of 35mm height and 25mm diameter. The 36mm diameter steel probe (TA-AACC36) adapted to the same texture analyzer was employed to perform a double consecutive compression at 2mm/s and a waiting period of 5s. From force-deformation curves, the textural parameters were obtained as follows: hardness is defined as the maximum peak force during the first compression cycle (first bite) and has often been substituted by the term firmness; cohesiveness is defined as the ratio of the positive force area during the second compression to that during the first compression. Cohesiveness may be measured as the rate at which the material disintegrates under mechanical action; adhesiveness is defined as the negative force area for the first bite and represents the work required to overcome the attractive forces between the surface of a food and the surface of other materials with which the food comes into contact and springiness relates to the height that the food recovers during the time that elapses between the end of the first bite and the start of the second bite (Rasper- Walker, 2000).

2.3.4 Sensory evaluation

Sensory evaluation was performed as a consumer acceptance testing, which was performed with 80 untrained panellist on the TTR and T2 using a hedonic test of five points: one point to “I dislike very much” and five point for “I like very much” (Anzaldua, 2005). Panelists were young people between 19 and 25 years old.

2.3.5 Statistical analysis

One-way ANOVA was used to determine the influence of OTP flour on rheological properties of gluten-free dough and pan bread (P<0.05). If significant difference was found, means were compared by using Tukey multiple comparison test (P<0.05) by using SigmaPlot 12.0 software.

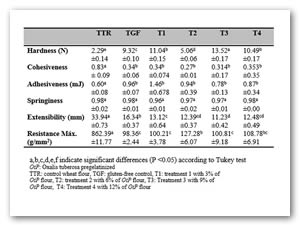

Table 1 shows the results for the TPA and extensibility test for pan bread dough. For the hardness parameter dough made from wheat is less hard than the gluten-free. The T2 is presented closer to wheat compared to the other treatments. TGF, T1, T3 and T4 as the addition of flour increased OtP increased hardness. For adhesiveness, gluten free treatments were more adhesives (P<0.05) compared to wheat, it could be that the dry formulation is gluten free base is almost entirely contains starches.

Table 1. TPA and Extensibility test for pan bread dough gluten free added with Oxalis tuberosa pregelatinized flour

In contrast to the dough with wheat, lacking gluten, other dough behave like dough streams, this is corroborated in the parameter cohesiveness where the dough does not tend to return to its original shape once it is removed the compression force feature that gives the wheat gluten network. It can be seen that there are significant differences (P<0.05) between the control dough and gluten-free even where the latter tend to recover 50% of its form. According to Lui (2003) analysis of the mechanical properties of dough are used as predictive analysis of the final product. In this case it finds that the hardness can be used as the main parameter of comparison, predicts that gluten-free breads will be harder than made from wheat.

Extensibility in wheat parameter shows an increase of over 100% compared with gluten free treatments can be seen that the gluten-free dough are very brittle, even in the samples tend to break more than one point.

With a compression of 20% in the hardness parameter presented significant differences (P<0.05) in all treatments being TTR less hard. For gluten-free bread flour increased OTP presented a decreased hardness relative to gluten free token from T2. Instead cohesiveness was higher in gluten-free breads compared with the control of wheat. This may be caused by the form that the bread and the percentage of deformation is imperceptible for wheat (Table 2).

Table 2. TPA test for pan bread gluten free added with Oxalis tuberosa pregelatinized flour

However according Demirkesen (2010) showed that gluten-free bread made only with rice flour and ligated with various gums, methylcellulose reduces the hardness of gluten-free products. Inferred that this type of gums gives greater formation of internal suspenders finally reflected in the crumb structure and imitate the gluten network. In this study it can be seen that the addition of flour OTP reduces hardness compared to TGF, in Figure 3 the cut made to the finished product which can be observed that the crumb structure is more compact for T3 and T4 as shown that indicates that it is harder. The TGF has cracks indicating that the structure is fragile, only T1 and T2 come closest to TTR. In the sensory evaluation the T2 chose for being the best present rheological characteristics compared to TTR, where no significant differences (P <0.05) in preference to any of the samples, with an average of 4.1 indicating that the panel "likes".

This study shows that the addition of OTP flour in gluten-free dough reduce the hardness if it’s compared whit the TGF. Although the extensibility is less compared whit TGF, the final product presents good characteristics in crumb structure. In the other hand the T2 present the closer comparable characteristics whit TTR. In sensory evaluation was demonstrated that the preference for a bread has not differences. May be the use for others starches, flours and gums can change the rheological parameters and increase the quality for the gluten-free products and make them comparable whit their counterparts with wheat.

Alfonso Totosaus, Hugo López and Norma Güemes Vera. (2013). Effect of Lupinus (Lupinus albus) and Jatropha (Jatropha curcas) protein concentrates on wheat dough texture and bread quality: optimization by a d-optimal mixture design. Journal of Texture Studies, 01-12, Mexico.

American Association of Cereal Chemist (AACC). (2000). Approved methods of the AACC. St Paul, MN, USA.

Anzaldua Morales, A.(2005). La evaluación sensorial de los alimentos en la teoria y la practica. Ed.Acribia. Spain.

Association of Official Analytical Chemists (AOAC). (1999). Official Methods of Analysis. Gaithersgurg. USA.

Bourne, M.C. (1978). Texture profile analysis. Food Technology, 32(7), 62-66.

Cajamarca Ruiz, Esther Elizabeth. (2010). Evaluacion nutricional de la Oca (Oxalis tuberosa) fresca, endulzada y deshidratada en secado de bandejas. Ecuador. Tesis para obtener el grado de Bioquimico Farmaceutico.

Fernandez Vasallo, Carlos. (2013). Harinas pregelatinizadas. Madrid: DACSA maiceras españolas SA Molendum, ingredientes y moliendas especiales, 22 de octubre de 2013, Vol. XXV Jornadas Técnicas AETC.

Ilkem Dermirkesen, Behic Mert, Gulum Sumnu, Serpil Sahin. (2010). Rheological properties of gluten-free formulations. Journal of Food Engineering, 96, 295-303. Turkey.

Ilkem Dermirkesen, Shivangi Kelkar, Osvaldo H. Campanella, Gulum Sumnu, Serpil Sahin, Martin Okos. (2014). Characterization of structure of gluten-free breads by using X-ray microtomography. Food Hydrocolloids, 36, 37-44. Turkey.

Kieffer, R., Weiser, H., Henderson, M.H. and Graveland, A. (1998). Correlations of breadmaking performance of wheat flour with rheological measurements on micro-scale. Journal of Food Science, 27, 53-60.

Lagrain Bert. (2013). Role of gluten and starch in crumb structure and texture of fresh and stored straight-dough bread.. Belgica: Inside Food Symposium.

M.E. Sánchez-Pardo, A. Ortiz-Moreno, F.J. García-Zaragoza, H. Necoechea-Mondragón, J.J Chanona-Pérez. (2012). Comparison of pound cake baked in two cycle microwave-toaster oven and in conventional oven. LWT Food Science and Technology, 46, 356-362, México.

Maria Elena Sanchez-Pardo, Alicia Ortiz-Moreno, Rosalva Mora-Escobedo, José Jorge Chanona-Pérez, Hugo Necoechea-Mondragón. (2008). Comparison of crumb microstructure from pound cakes baked in a microware or conventional oven. LWT Food Science and Technology,41, 620-627. México.

Rasper, V. F. & Walker, C. E. (2000). Quality evaluation of cereals and cereal products: in Handbook of Cereal Science and Technology, 505-537.

WGO, World Gastroenterology Organisation Global Guidelines. (2012). Celiac disease.

Z. Liu & M.G. Scanlon. (2003). Predicting mechanical properties of bread crumb. Trnas IChemE, 81, 22-238. Canada.

[a] aInstituto de Ciencias Agropecuarias (ICAp) de la Universidad Autónoma del Estado de Hidalgo (UAEH).

[b] bDepartamento de graduados e investigación en alimentos, Escuela Nacional de Ciencias Biológicas del Instituto Politécnico Nacional (IPN).